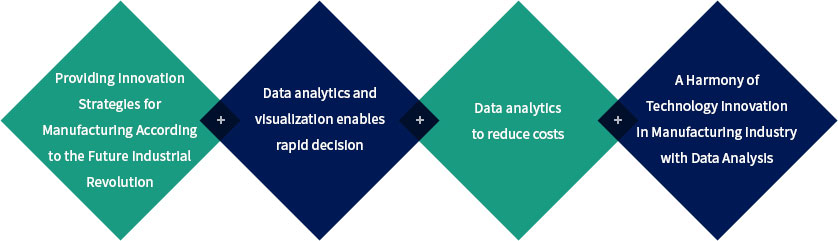

AMPAnalysis of manufacturing big data service

( )

)

Analysis of manufacturing big data and monitoring services

Data, Seeing is the beginning, Let’s do on the analyzed data

Manufacturing big data analysis and monitoring services

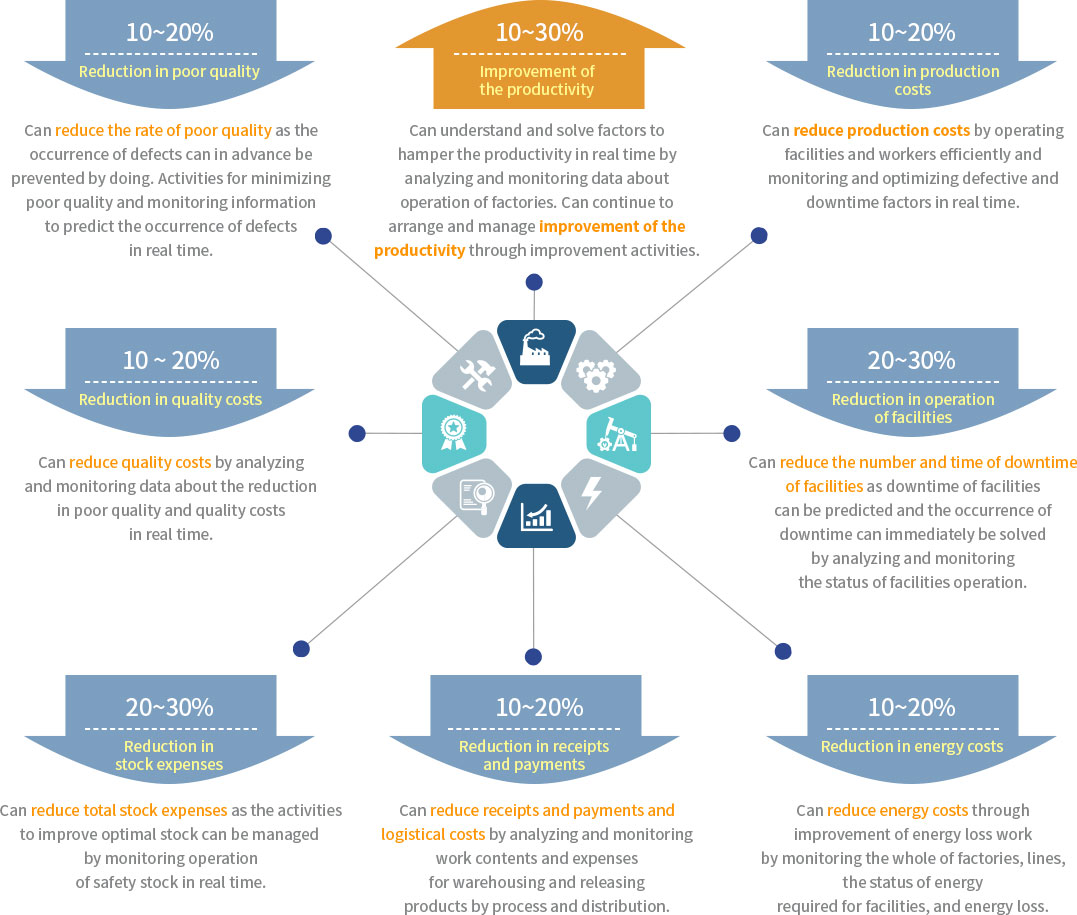

Quantitative effects

Primary functions of the system – Functional block diagram

-

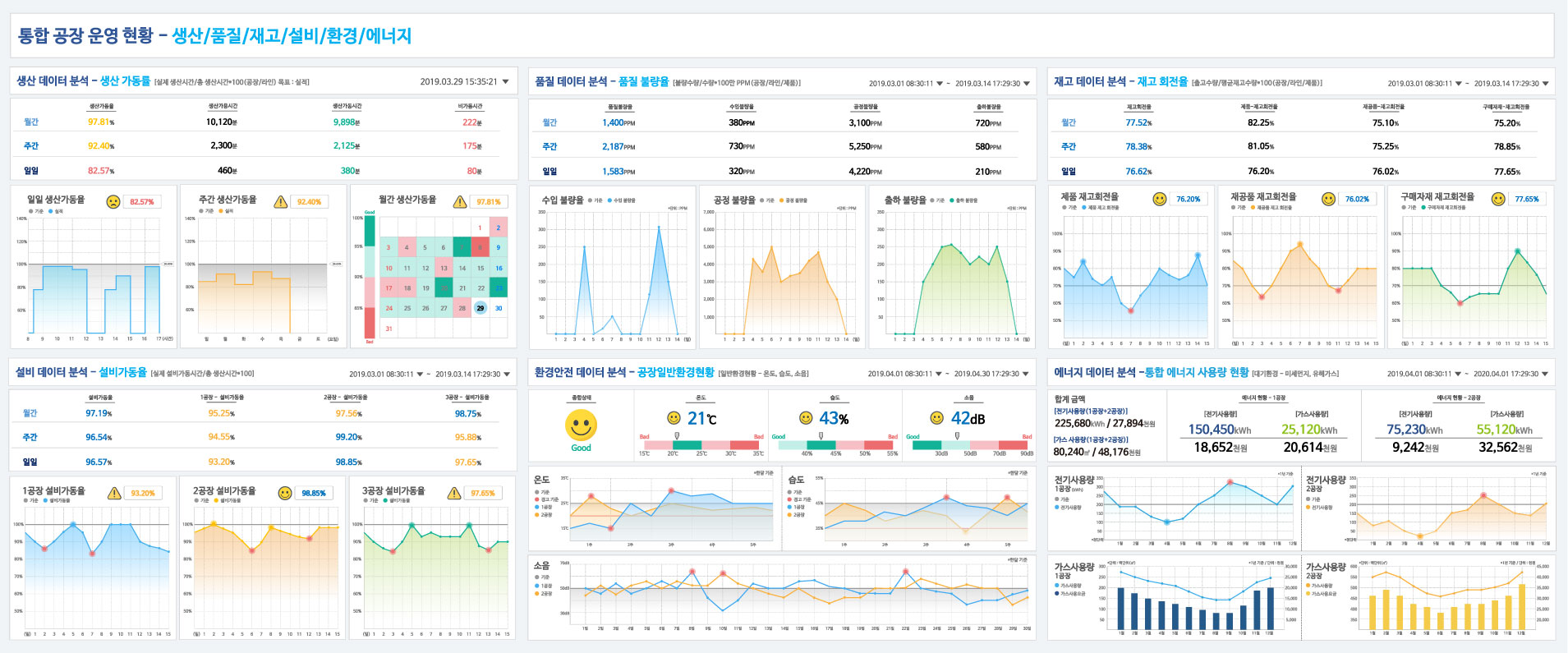

Status of integrated operation of factories

- ·Optimizing operational efficiency of the whole factories.

- ·Minimizing operational loss.

- ·Improving the operational ability through improvement activities.

-

Status of integrated predictive analyses

- ·Predicting operational efficiency of factories and preventing problems in advance.

-

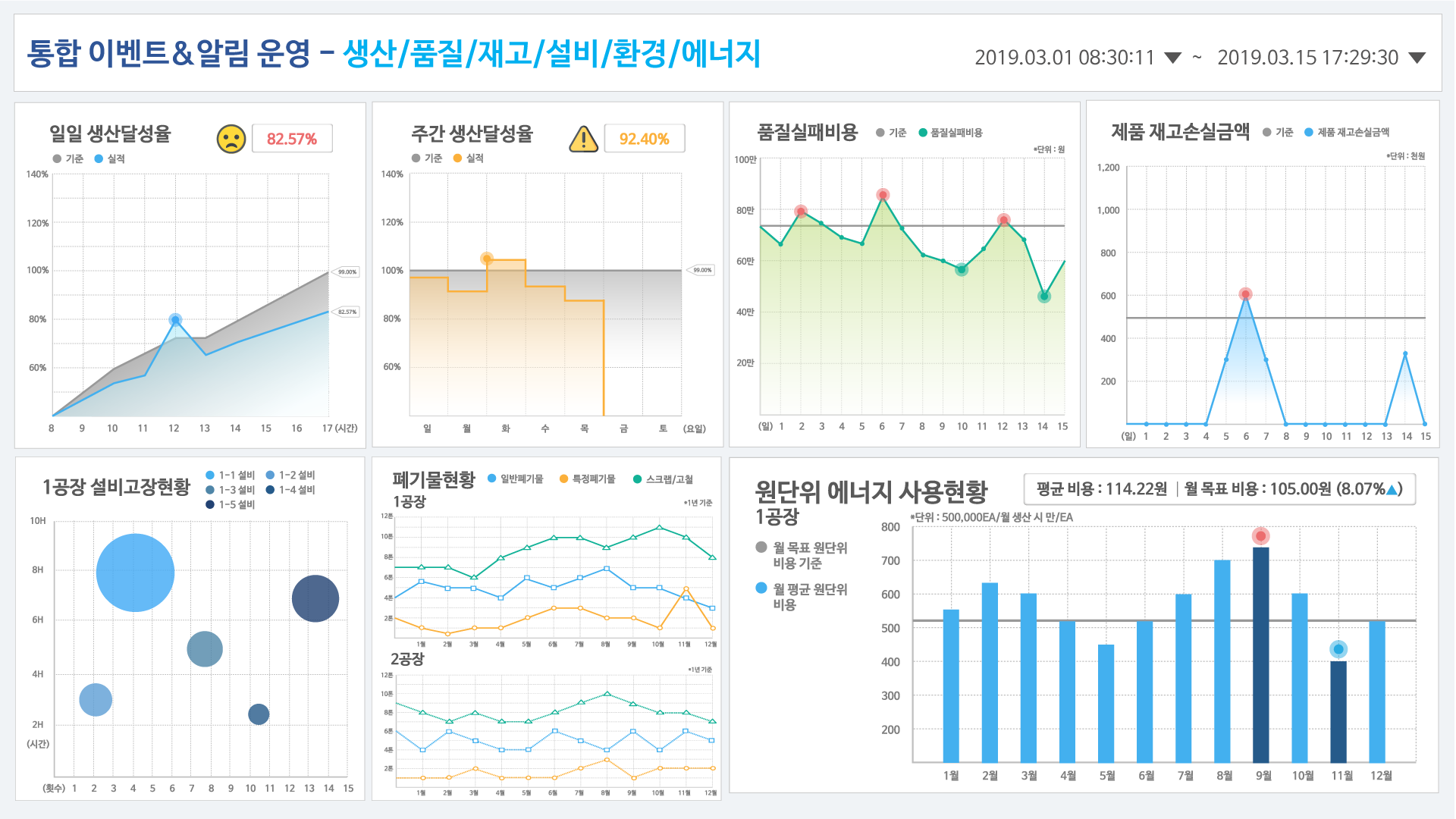

Status of integrated events/notices

- ·Solving problems promptly by events and notices.

-

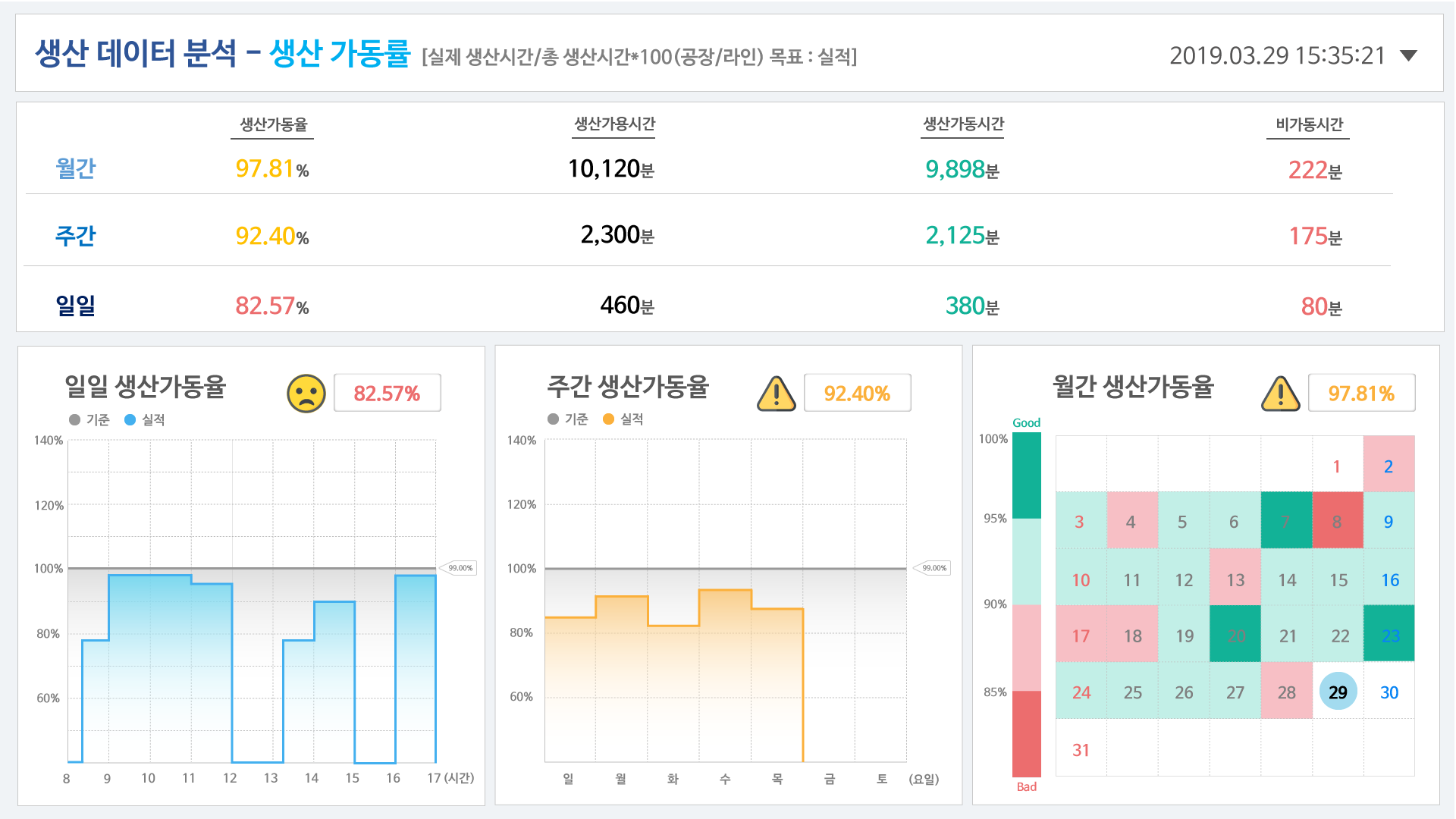

Status of production

- ·Analyses of productive capacity

- ·Analyses of production plans

- ·Analyses of production execution

- ·Analyses of actual outputs

- ·Analyses of production improvement

- ·Analyses of production prediction

-

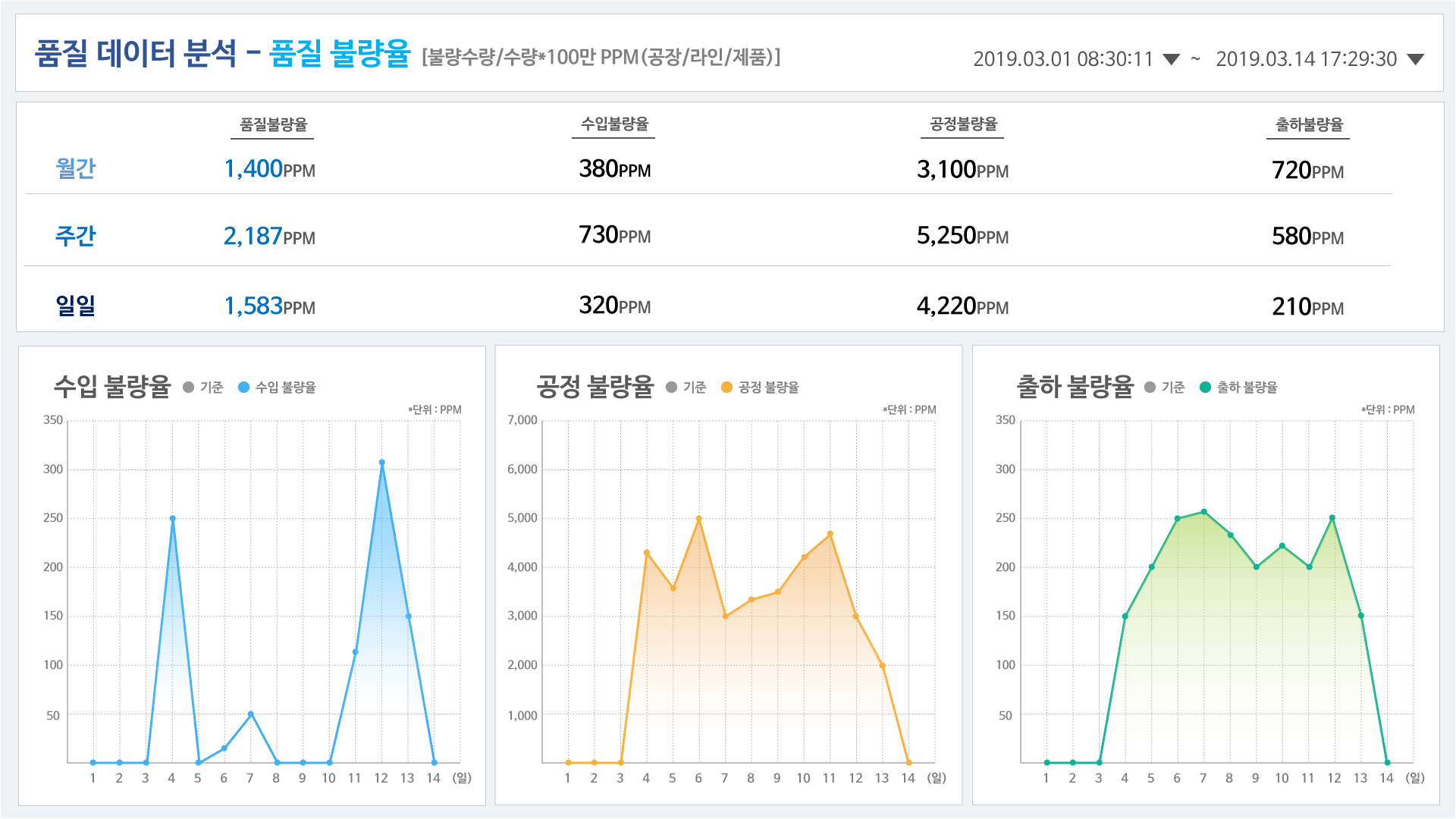

Status of quality

- ·Analyses of quality costs

- ·Analyses of quality prevention

- ·Analyses of quality evaluation

- ·Analyses of quality failure

- ·Analyses of quality improvement

- ·Analyses of quality prediction

-

Status of stock

- ·Analyses of receipts and payments

- ·Analyses of stock management

- ·Analyses of stock improvement

- ·Analyses of stock prediction

-

Status of facilities

- ·Analyses of facility ability

- ·Analyses of facility operation

- ·Analyses of maintenance activities

- ·Analyses of maintenance expenses

- ·Analyses of facility improvement

- ·Analyses of facility prediction

-

Status of environment safety

- ·Analyses of the status of environment

- ·Analyses of environment inspection

- ·Analyses of environment improvement

- ·Analyses of environment prediction

- ·Analyses of the status of safety

- ·Analyses of safety inspection

- ·Safety improvement analyses

- ·Analyses of safety prediction

-

Status of energy

- ·Analyses of energy usage

- ·Analyses of energy costs

- ·Analyses of energy plans

- ·Analyses of energy improvement

- ·Analyses of energy prediction

※ The predictive analysis function is optional.

Contact

- 1544-7603, 010-3388-4748 Jung Hyun Park, head of department

- 050-4981-7603

- service@epm-solutions.net